Table Of Contents

Tools and Materials Required for Relining

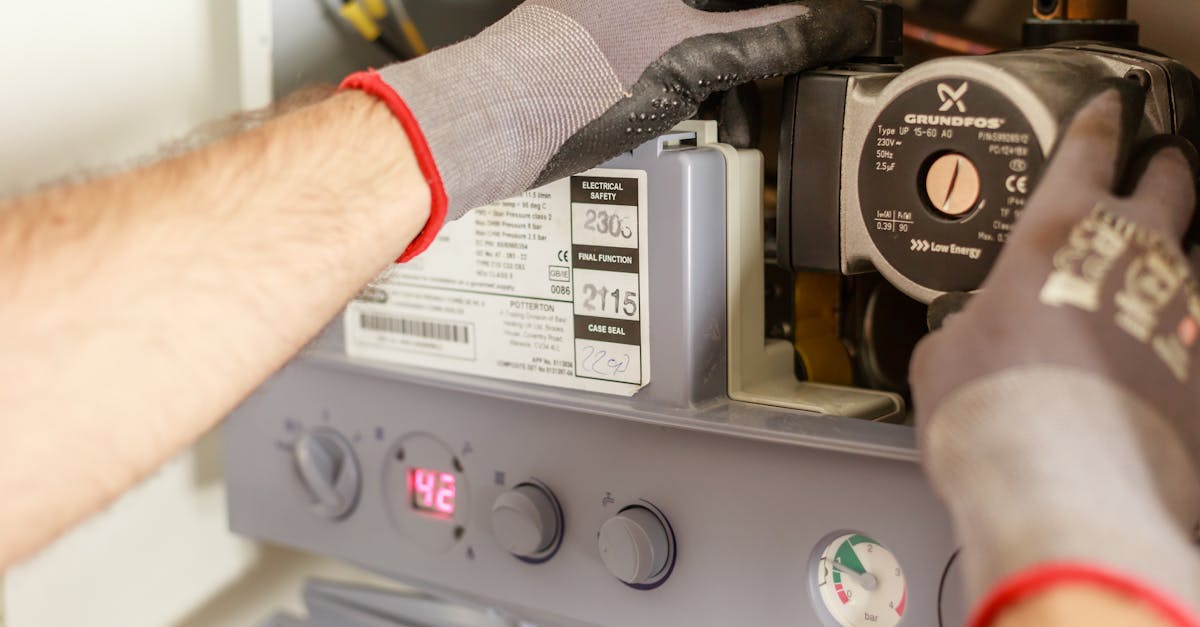

When preparing for a pipe relining project, having the right tools and materials is crucial. Essential items typically include a sewer camera for inspecting the interior condition of the pipe. A high-pressure water jetting system can be used to clear debris and blockages. Additionally, you'll need a relining epoxy resin or felt liner that will form the new pipe wall inside the existing cast iron structure. Specialized equipment for applying the liner, such as a winch or a nozzle, will also be necessary to ensure proper installation.

Safety gear is an important consideration when tackling pipe relining. Goggles, gloves, and potentially respirators will help protect against harmful chemicals and debris. Be mindful of the condition of your tools as well, ensuring that everything is in working order before starting the relining process. Having a comprehensive checklist can help streamline the setup and avoid any interruptions during the job, making the relining process more efficient and effective.

Essential Equipment for a Successful Job

When preparing for pipe relining, specific equipment is crucial to ensure the process is effective and efficient. A high-quality camera system is essential for inspecting the interior of the sewer pipes. This allows for a thorough assessment of the damage and helps determine the appropriate method for relining. Additionally, a drainage cleaning machine is important for removing debris and blockages, which can compromise the integrity of the relining material. Having these tools on hand sets the foundation for a successful relining project.

Another vital piece of equipment is the resin application system, which transports and applies the epoxy material used in the relining process. This system ensures an even and effective application, leading to a better seal within the pipes. Additionally, inflatable relining bladders are necessary for holding the lining in place as it cures. They provide support and ensure the newly applied material adheres properly to the existing pipe walls, enhancing the overall strength and functionality of the sewer system post-relining.

Professional vs. DIY Relining

When considering pipe relining, homeowners often have to choose between hiring professionals or tackling the job themselves. Professional relining services come with expertise in diagnosing issues, selecting appropriate materials, and ensuring the job is completed to code. These specialists have access to advanced equipment, which can make the process more efficient and potentially more long-lasting, ultimately reducing the chances of future complications.

On the other hand, DIY pipe relining can be appealing for those looking to save money and gain hands-on experience. Homeowners may find various kits available for purchase that simplify the process. However, successful DIY relining requires significant knowledge of plumbing systems as well as familiarity with the tools needed. Mistakes in this process can lead to improper installation, leaving the sewer system vulnerable to further damage.

Pros and Cons of Each Approach

When considering pipe relining, opting for a professional service can offer several advantages. Professionals possess specialized equipment and expertise that ensure a thorough and effective relining process. Their experience allows for quicker assessment of the sewer system's condition and minimizes the risk of further damage during the procedure. Additionally, most professional services provide warranties, giving homeowners peace of mind regarding the longevity of the repair.

On the other hand, DIY pipe relining can be a cost-effective option for those willing to invest the time and effort. Homeowners with some plumbing experience may find it satisfying to take on this project themselves. However, without the right tools and knowledge, mistakes can lead to ineffective results and additional costs down the line. It’s crucial to weigh the potential savings against the risks of inadequate relining when deciding on this approach.

Indicators That Relining is Necessary

Several signs can indicate that pipe relining is necessary for a cast iron sewer pipe. Homeowners may notice slow draining or frequent clogs in their plumbing system. These symptoms often suggest that there is damage within the pipe, such as cracks or invasive tree roots blocking the flow of wastewater. Foul odors emanating from drains can also be a clear indication of sewer line issues, prompting the need for inspection and potential relining.

In addition to clogs and odors, visible signs of deterioration should not be overlooked. Cracked or rusted sections of the cast iron pipe may become evident during a thorough inspection. A professional may utilize advanced camera technology to assess the interior of the pipe, identifying areas in need of relining. Addressing these problems promptly can prevent more extensive repairs and ensure the plumbing system functions efficiently for years to come.

Signs of Sewer Pipe Damage

Identifying signs of damage in cast iron sewer pipes is crucial for maintaining a functional waste removal system. Homeowners should be on the lookout for recurring clogs, which may point to an obstruction or deterioration within the pipe. Unpleasant odors emanating from the plumbing can also indicate issues, such as cracks or breaks allowing sewage gases to escape. Water pooling in unusual areas around the home may suggest leaks from the sewer line, further emphasizing the need for prompt assessment.

When visible structural issues occur, such as rust or corrosion on the exterior of the pipe, this confirms the need for immediate action. Changes in water drainage patterns, like slow draining sinks or backups, can signify underlying damage as well. In many cases, these indicators may necessitate pipe relining, an effective method for restoring the sewer line without requiring full replacement. Proactive monitoring can help prevent extensive damage and expensive repairs in the long run.

FAQS

Can you reline a cast iron sewer pipe?

Yes, a cast iron sewer pipe can be relined using specialized techniques and materials designed for this type of plumbing.

What tools and materials are needed for relining a cast iron sewer pipe?

Essential tools and materials include a relining kit, epoxy resin, a tube or hose for applying the resin, a cutter for preparing the pipe, and protective gear such as gloves and goggles.

Is it better to hire a professional or attempt a DIY relining?

It depends on your experience and comfort level. Hiring a professional ensures the job is done correctly, while DIY can save money but may require specific skills and knowledge.

What are the signs that relining a sewer pipe is necessary?

Indicators that relining may be needed include frequent clogs, slow drainage, visible leaks, or unusual odors coming from the plumbing system.

How long does a relining job typically take?

The duration of a relining job can vary based on the extent of damage, but it generally takes a few hours to a day to complete the process.