Table Of Contents

Professional vs. DIY Relining

Professional pipe relining services offer a comprehensive solution with trained technicians equipped to handle various challenges. They utilize advanced technology and materials that can ensure a more durable and efficient relining process. Professionals often provide warranties, giving homeowners peace of mind regarding the longevity of the repair. Their experience can also help avoid common pitfalls found in DIY attempts, making for a smoother project overall.

On the other hand, DIY pipe relining can be an appealing option for those aiming to save money and take on a hands-on project. Homeowners may find satisfaction in learning the process and completing the task independently. However, this approach carries risks, such as improper installation or use of subpar materials, which can lead to further complications down the line. Knowledge and experience level will significantly influence the outcome of the DIY method, making careful consideration crucial before proceeding.

Pros and Cons of Each Approach

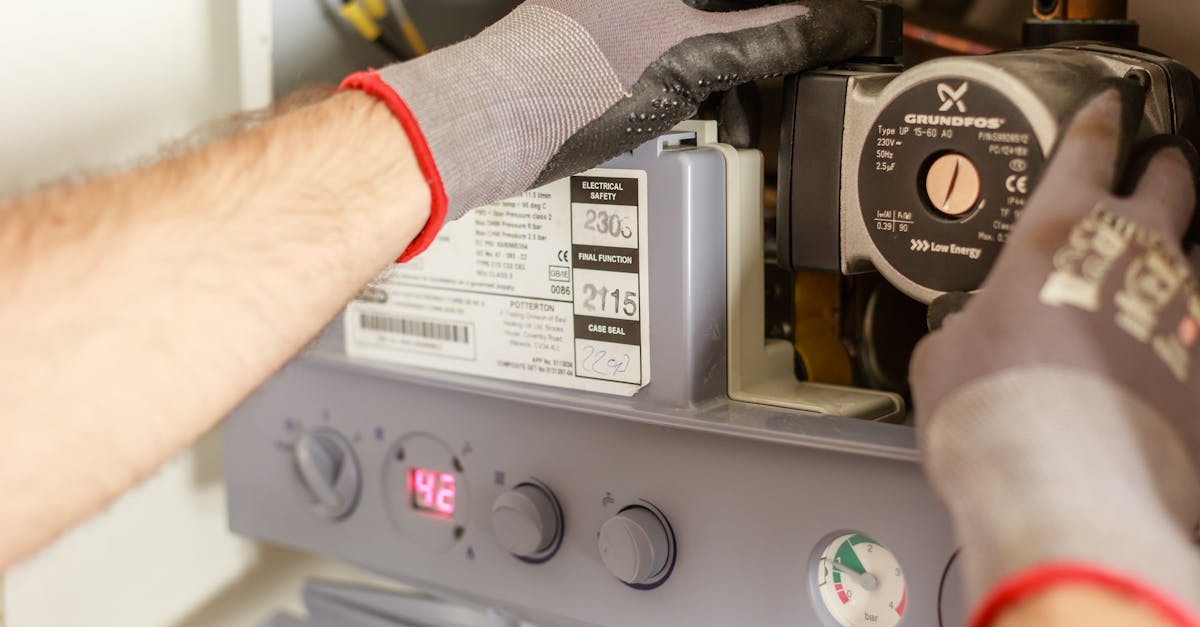

Professional pipe relining offers numerous advantages, particularly in terms of expertise and reliability. Skilled technicians bring extensive knowledge to the process, ensuring that the relining is executed with precision. They often have access to advanced equipment, allowing for thorough inspections and a more effective relining technique. This ensures a longer-lasting solution, reducing the risk of future complications. However, the downside can be the cost; professional services may be priced higher than DIY methods, which can deter some homeowners.

On the other hand, DIY pipe relining can be more budget-friendly and appealing for those willing to tackle home improvement projects. Homeowners can save money on labor costs and feel a sense of accomplishment after completing the job. Nevertheless, this approach carries risks. Lack of experience may lead to improper installation, which could result in more significant issues down the road. Additionally, the absence of professional-grade tools may hinder the quality of the relining process, ultimately affecting the longevity and effectiveness of the repairs.

Potential Challenges in Relining

Pipe relining offers a practical solution for damaged plumbing, but several challenges can arise during the process. One major concern is the condition of the existing pipes. If there are significant structural failures or blockages, relining may not be effective or possible. The age and material of the original pipes can also impact the success of the relining process, as older PVC may have unique issues that complicate repairs.

Another challenge is the technique and equipment required for successful relining. High-quality materials and specialized tools are crucial for achieving a long-lasting result. Poor application or the use of inferior materials can lead to premature failures or further damage. Additionally, inexperienced technicians may encounter difficulties that could prolong the project and increase costs. Proper assessment and planning are essential to navigate the complexities of pipe relining.

Common Issues Encountered

During pipe relining, several common issues can arise that may hinder the process. One significant problem is the presence of existing blockages or debris within the pipes. These obstructions can prevent the relining material from properly adhering to the pipe walls. Inadequate cleaning before the relining process can lead to further complications, such as uneven surfaces that compromise the integrity of the new liner.

Another challenge faced during pipe relining is the temperature and curing time of the resin used. If the ambient temperature is too low or too high, it can affect how the resin hardens. This variability may result in a liner that is not sufficiently cured, leading to potential failures in performance. Proper monitoring and adherence to the manufacturer's guidelines are crucial to ensure that the relining is successful and long-lasting.

Maintenance After Relining

After undergoing pipe relining, regular maintenance is crucial to ensure the longevity and effectiveness of the newly installed lining. Keeping an eye on the condition of both the pipes and the relining material helps catch potential issues early. Homeowners should consider scheduling periodic inspections, as this will allow professionals to gauge the integrity of the lining and address any minor problems before they escalate.

Additionally, maintaining a clean drainage system can significantly enhance the performance of relined pipes. Avoiding the disposal of grease, large food particles, or non-biodegradable materials down the drain prevents clogs that can damage the lining. Simple preventive measures, like using drain strainers and regularly cleaning out any debris, can go a long way in preserving the benefits of pipe relining for years to come.

Tips for Extending Pipe Life

Regular maintenance is crucial for extending the life of PVC pipes. Routine inspections can catch potential issues early, preventing significant damage and costly repairs. Cleaning the pipes periodically helps eliminate buildup that can impair flow and lead to leaks. Staying ahead of corrosion and blockages ensures the system functions optimally.

Investing in quality pipe relining can also enhance the durability of existing pipes. This process not only repairs damaged sections but also adds a new layer of protection. Avoiding harsh chemicals in your cleaning regimen helps preserve the integrity of the pipes. Consider using filters or screens to block debris from entering the system, further safeguarding the longevity of your plumbing.

FAQS

Can PVC pipes be relined?

Yes, PVC pipes can be relined using various methods that involve inserting a new lining material to restore their functionality and extend their lifespan.

What are the advantages of professional relining over DIY methods?

Professional relining offers expertise, specialized equipment, and a higher quality of work, ensuring that the job is done correctly and efficiently, while DIY methods may save money but can lead to improper installation and potential issues.

What common issues can arise during the relining process?

Common issues during relining include misalignment of the new liner, inadequate curing of materials, and the presence of debris or blockages that can hinder the process.

How can I maintain my PVC pipes after relining?

To maintain PVC pipes after relining, regularly inspect for leaks, avoid flushing inappropriate materials, and schedule professional maintenance to ensure continued performance.

Is relining a cost-effective solution for damaged PVC pipes?

Yes, relining can be a cost-effective solution, as it often costs less than replacing the entire pipe system while providing similar benefits in terms of longevity and performance.