Table Of Contents

Choosing the Right Contractor

Selecting a qualified contractor for pipe relining is essential to ensure a successful and long-lasting repair. Look for professionals who specialize in this specific type of service. Their expertise will greatly influence not only the quality of the work but also the efficiency of the repair process. It's beneficial to check their credentials, as well as reviews from previous clients, to gauge their reputation.

Experience plays a critical role in the pipe relining process. Contractors with extensive hands-on experience are more likely to be familiar with various pipe conditions and the appropriate methods for relining. Ask potential contractors about their training and the technologies they use. Clear communication throughout the project also contributes to a positive experience, so prioritize a contractor who takes the time to explain the process and address any concerns.

Key Qualifications to Look For

When selecting a contractor for pipe relining, it's crucial to prioritize experience and specialized training. A contractor with a proven track record in pipe relining can ensure a successful installation and minimize future issues. Look for certifications and qualifications that demonstrate their expertise in this specific service. Training in current technologies and techniques also indicates that the contractor stays updated with industry advancements, which can significantly impact the project's outcome.

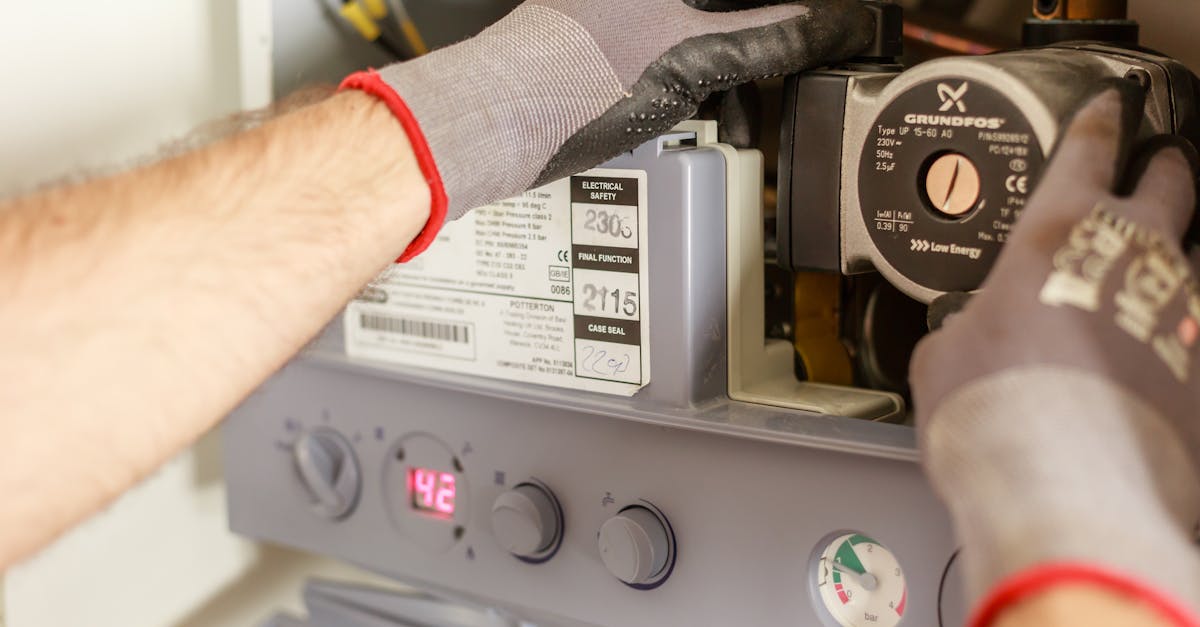

Another important qualification to consider is the availability of proper equipment. Pipe relining requires specific tools and technology to perform effectively. Contractors should have access to high-quality materials and advanced machinery designed for the relining process. This not only helps in achieving a smooth and durable finish but also reduces the likelihood of complications during the installation. Be sure to ask potential contractors about the equipment they use to ensure they meet the necessary standards for pipe relining projects.

Additional Costs to Consider

When budgeting for pipe relining in Australia, it's crucial to factor in additional costs that may arise during the process. While the primary expense often covers labor and materials, unexpected repairs or prep work might be necessary for older or more damaged pipes. Services such as cleaning the pipes prior to relining or making adjustments to the surrounding areas can add to the overall cost. It's advisable to request a detailed estimate from contractors to understand the full financial scope of the project.

Permits and inspections are also significant components to keep in mind. Depending on local regulations, obtaining the proper permits can incur extra fees. Inspections might be required both before and after the pipe relining work is completed to ensure compliance with safety standards and local building codes. These additional expenses can vary widely based on the municipality and the specific requirements for plumbing work in the area.

Permits and Inspections

Before proceeding with pipe relining, it's essential to understand the local regulations surrounding plumbing work. Most areas in Australia require homeowners to obtain permits prior to starting any significant plumbing projects, including pipe relining. These permits ensure that the work follows safety standards and complies with building codes. Consulting with local authorities and having the correct documentation can prevent fines and project delays.

Inspections often accompany these permits to verify that the work is performed correctly and meets all legal requirements. A qualified inspector may evaluate the project at various stages, ensuring the relined pipes are safe and suitable for use. This step not only protects your investment but also helps maintain the integrity of the plumbing system in the long run. Keeping clear communication with your contractor about necessary inspections can streamline the process and ensure compliance.

Maintenance Tips PostRelining

After pipe relining is completed, regular maintenance will significantly enhance the longevity and performance of the newly installed lining. It is important to avoid flushing non-biodegradable items down the toilet or pouring grease down the sink, as these can create blockages and potentially damage the lining. Establishing a routine inspection schedule is beneficial for monitoring the condition of the pipes and quickly addressing any emerging issues.

Furthermore, using biodegradable cleaners can help maintain a clean environment within the pipes while being gentle on the relined surface. Keeping an eye on water pressure and flow rates can also provide insight into the inner workings of your plumbing. If any abnormalities are noticed, consulting a professional for immediate advice is advisable. Timely intervention can prevent larger problems from developing and prolong the life of the pipe relining.

Enhancing Longevity of Relined Pipes

Proper maintenance is essential for enhancing the longevity of relined pipes. Regular inspections can help identify any potential issues before they escalate. Keeping an eye on your property’s drainage system ensures that sediment or debris does not accumulate, which could compromise the integrity of the relined pipes. It's also advisable to avoid pouring harsh chemicals down the drain, as they can degrade the lining material over time.

Additionally, implementing preventive measures can greatly extend the life of your pipe relining. Consider using filtered strainers on sinks and drains to catch food particles and hair. This simple step can minimize buildup inside the pipes. Ensuring that trees near the plumbing are monitored can prevent root intrusion, which often poses a threat to the effectiveness of relined pipes. Maintaining a proactive approach will provide lasting benefits and maintain optimal functionality.

FAQS

What is the average cost to reline PVC pipe in Australia?

The average cost to reline PVC pipe in Australia typically ranges between AUD 150 to AUD 300 per meter, depending on various factors such as the size of the pipe and the extent of damage.

Are there any additional costs involved in the relining process?

Yes, additional costs may include permits and inspections, pre-relining cleaning, and potential repairs needed before the relining can take place.

How can I find a qualified contractor for PVC pipe relining?

Look for contractors with experience in pipe relining, appropriate licenses, positive customer reviews, and references. It’s also beneficial to check for certifications in relevant plumbing and repair techniques.

How long does the relining process usually take?

The relining process can vary in duration but generally takes between a few hours to a couple of days, depending on the length of the pipe being relined and any necessary preparatory work.

What maintenance is required after relining PVC pipes?

After relining, it is essential to maintain the pipes by regularly inspecting them for leaks, avoiding the disposal of inappropriate materials down the drain, and ensuring that tree roots are managed to prevent future issues.