Table Of Contents

Challenges in Relining Galvanized Pipes

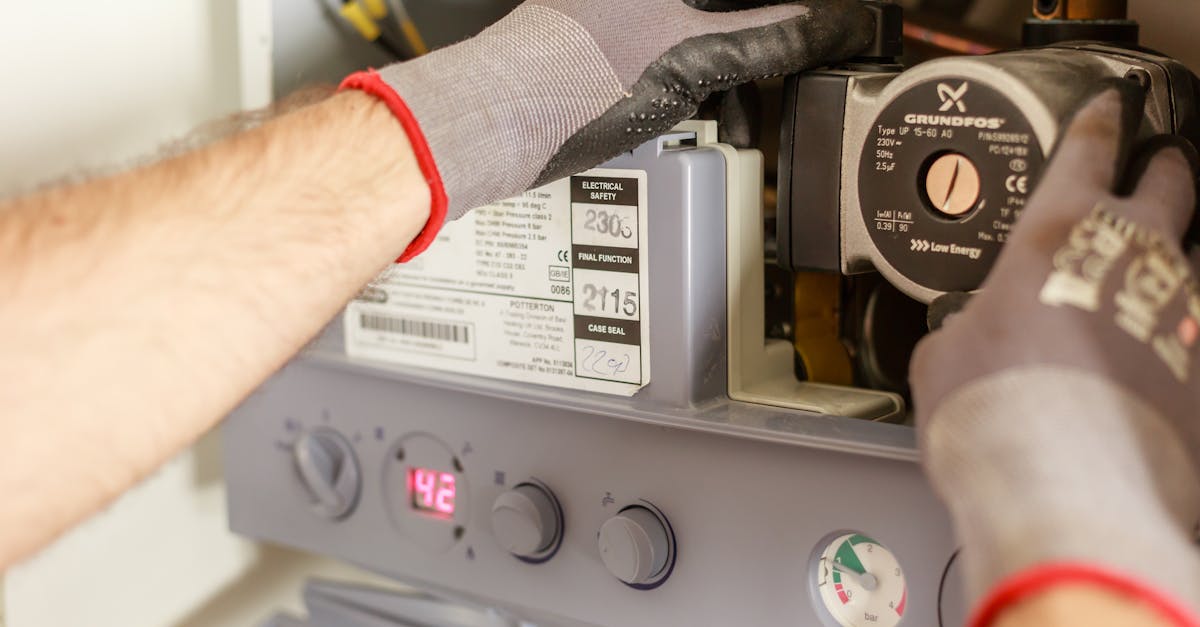

Relining galvanized pipes presents several challenges that can complicate the process. One major issue is the rough interior surface typical of older galvanized pipes, which can hinder the adhesion of the relining material. This roughness can lead to bubbles or weaknesses in the relined structure, ultimately affecting its long-term durability. Additionally, the existing corrosion within these pipes can create uneven areas that complicate the relining process further.

Another significant challenge comes from the age and potential fragility of galvanized pipes. As these pipes age, they may develop cracks or breaks that are not easily visible. During the pipe relining process, these imperfections can become problematic, as they may require additional repairs before a successful lining can be applied. Moreover, if the pipes have extensive deterioration, relining might not provide the necessary benefits, leading to decisions about replacement rather than maintenance.

Potential Issues and Limitations

Pipe relining can introduce various issues and limitations, particularly when dealing with galvanized pipes. These pipes often have internal corrosion, which can compromise the integrity of the relining material. The presence of rust and scaling can prevent proper adhesion of the new lining, leading to potential leaks or outright failure of the repair. Additionally, the age of the pipes may contribute to uneven surfaces that hinder the smooth application of the liner, further complicating the relining process.

Another significant concern involves the versatility of pipe relining itself. Not all types of damage or deterioration can be effectively addressed through relining methods. Severe structural defects, such as extensive corrosion or sudden bends in the piping, may necessitate replacement rather than relining. In instances where existing plumbing systems are already undersized or poorly configured, attempting to reline might not yield satisfactory results, potentially leading to ongoing problems down the line.

Alternative Solutions to Relining

When faced with the challenges of galvanized pipes, homeowners often seek alternative solutions to pipe relining. One common option is replacement, which may provide a long-term fix for deteriorating plumbing systems. By installing new pipes, property owners can eliminate issues such as corrosion and water contamination. While this route can be more expensive and disruptive, it often leads to improved water flow and longevity compared to maintaining older pipes.

Another valuable approach is the use of trenchless technology for pipe replacement. This method minimizes excavation, allowing for the installation of new pipes without extensive digging. Trenchless techniques can significantly reduce repair time and costs while preserving the landscape. Although pipe relining offers a less invasive solution for many situations, these alternatives may be preferable depending on the specific condition of the existing plumbing and the goals of the homeowner.

Replacement vs. Relining

Replacement of galvanized pipes often involves significant labor and material costs. Homeowners may face disruptions during the installation process, impacting daily routines. Conversely, pipe relining serves as a less invasive method, allowing existing pipes to remain in place while reinforcing their structural integrity. This technique can effectively extend the lifespan of the plumbing system without the need for extensive excavation work.

However, pipe relining may not address all underlying issues that aged galvanized pipes encounter. In cases of severe corrosion or structural damage, replacement might still be the more effective option. It's important to assess the condition of the pipes thoroughly before making a decision. Evaluating both options enables homeowners to make informed choices that best suit their plumbing needs and budget constraints.

Maintenance Tips for Relined Pipes

Regular maintenance is essential for the longevity of relined pipes. Begin by inspecting for any signs of leaks or unusual water flow in the system. Periodic checks can help identify potential issues before they escalate into more significant problems. Keeping the area around the pipes clear of debris will also aid in ensuring that the relined structure remains intact and functioning effectively.

Additionally, consider performing routine cleaning of drains connected to relined pipes. This helps prevent the buildup of sludge or other blockages that could compromise the integrity of the pipe relining. Using enzymatic cleaners can be beneficial as they are less abrasive than harsh chemicals. Staying proactive with these maintenance practices will enhance the lifespan of your relined pipes significantly.

How to Extend the Life of Your Relined Pipes

Maintaining relined pipes requires attention to the surrounding environment and regular inspection. Keep an eye out for any signs of leaks or unusual wear around the relined areas. Proper drainage and venting will help minimize moisture buildup, which can compromise the integrity of the relining material. Additionally, monitoring water pressure helps prevent unnecessary stress on the pipes.

Using appropriate cleaning methods will also contribute to the longevity of pipe relining. Avoid using harsh chemicals that could damage the lining material. Instead, opt for gentle cleaners specifically designed for use with relined surfaces. Conducting routine maintenance checks can identify potential issues early. Taking these precautions ensures that the relined pipes perform optimally for an extended period.

FAQS

Can galvanized pipes be relined?

Yes, galvanized pipes can be relined, but there are several challenges and limitations associated with the process that need to be considered.

What are the main challenges in relining galvanized pipes?

The main challenges include the buildup of corrosion inside the pipes, which can affect the adhesion of the relining material, and the potential for existing leaks that may complicate the relining process.

What are the potential issues and limitations of relining galvanized pipes?

Potential issues include reduced water flow due to the thickness of the lining, difficulty in accessing certain sections of the piping, and the possibility that relining may not fully address underlying problems such as severe corrosion or structural damage.

How does relining compare to replacing galvanized pipes?

Relining can be less disruptive and more cost-effective than replacement, but it may not provide a long-term solution if the pipes are extensively damaged. Replacement may be a better option for significantly deteriorated systems.

What maintenance tips can help extend the life of relined pipes?

To extend the life of relined pipes, regularly check for leaks, maintain proper water pressure, avoid harsh chemicals, and schedule periodic inspections to ensure the integrity of the relining material.