Table Of Contents

Required Certifications for Gas Plumbers

To become a qualified gas plumber, individuals must obtain specific certifications that demonstrate their knowledge and skills in handling gas systems. These certifications are typically provided by state or national organizations, ensuring that gas plumbers adhere to safety standards and regulations. The requirements may vary by location, so prospective gas plumbers should verify the regulations applicable in their area. Completing a recognized training program is often a prerequisite for certification, helping to ensure that they understand the complexities of gas systems.

In addition to certification from recognized bodies, gas plumbers may need to pass exams that assess their understanding of relevant codes and safety procedures. Ongoing education is also crucial in this field. Many gas plumbers are required to complete continuing education courses to keep their certifications current and stay informed about new technologies, techniques, and legislative changes. This commitment to professional development sets qualified gas plumbers apart in terms of reliability and safety assurance for their clients.

Licensing and Training for Gas Specialists

Gas plumber certification requires specific training that focuses on gas-related systems and their safety. Prospective gas plumbers typically complete a combination of classroom instruction and hands-on experience. This education covers topics such as gas line installation, maintenance, and regulations.

In addition to training, gas plumbers must obtain the appropriate licenses to work legally within their state or locality. This process often involves passing exams that demonstrate knowledge of gas codes and safety practices. Continuous education may also be necessary to remain updated on changes in regulations and technology.

Tools Used by Plumbers

Plumbers rely on a variety of essential tools to perform their tasks effectively. Wrenches, pipe cutters, and plungers are basic equipment every plumber carries. These tools are crucial for tasks like tightening fittings, cutting pipes to the necessary lengths, and clearing clogs from drains. The ability to use these tools proficiently can significantly impact the efficiency and quality of a plumber's work.

In contrast, a gas plumber uses specialized equipment due to the unique challenges associated with gas systems. Tools like gas pressure gauges and leak detection devices are integral to their work. While both general plumbers and gas plumbers may share some tools, the safety protocols and requirements in gas plumbing necessitate additional equipment specifically designed for handling gas lines and appliances.

Essential Equipment for Traditional Plumbers

Traditional plumbers rely on a variety of essential tools to effectively complete their work. Common gear includes wrenches, pipe cutters, and plungers. Wrenches are crucial for tightening and loosening fittings or connections, while pipe cutters help ensure clean cuts in various types of piping. Additionally, plungers are indispensable for clearing clogged drains and toilets, allowing for efficient problem-solving in residential and commercial settings.

While gas plumbers focus on gas line installation and maintenance, traditional plumbers primarily deal with water supply systems and drainage. This specialization necessitates different tools tailored to their specific tasks. Equipment such as drain snakes and pipe inspection cameras enable plumbers to diagnose and resolve issues with pipes and drains. By utilizing these tools, traditional plumbers can maintain the integrity of water systems and ensure reliable service for their clients.

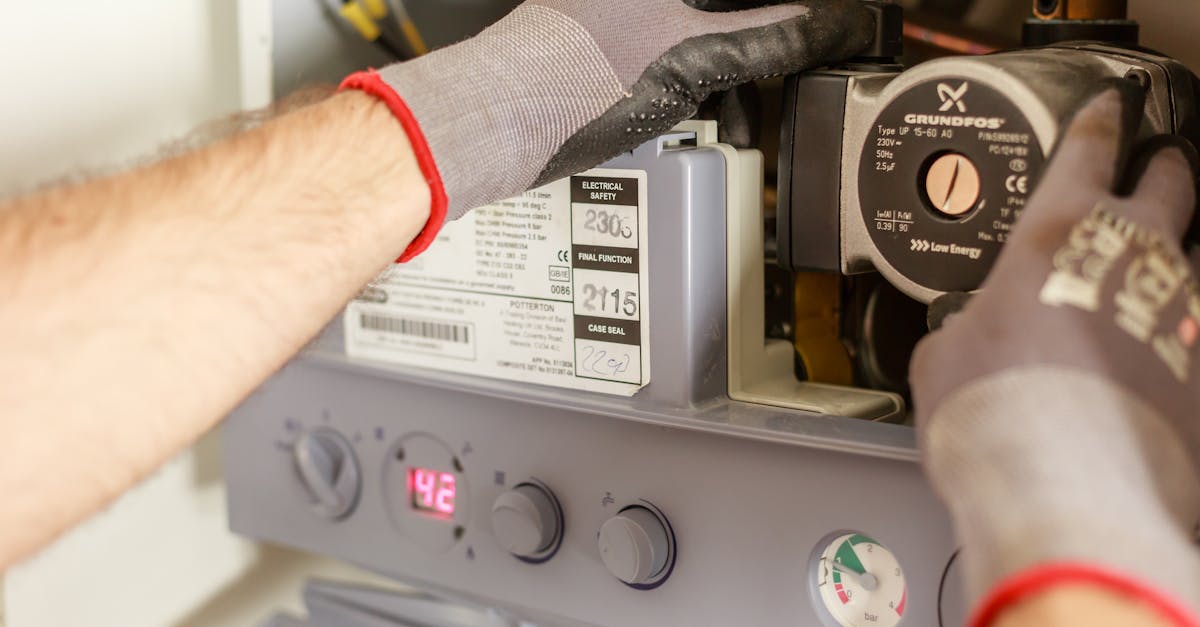

Tools Used by Gas Plumbers

Gas plumbers rely on a specialized set of tools designed for working with gas lines and appliances. These tools include pipe wrenches, gas leak detectors, and pressure gauges. A gas plumber often employs flexible gas line fittings to ensure proper connections while maintaining code compliance. Adequate testing tools are also crucial for assessing the safety and functionality of gas installations.

Additionally, gas plumbers utilize various cutting and crimping tools to shape and fit gas piping to secure joints effectively. Safety equipment, such as personal protective gear and proper ventilation devices, plays a vital role in their work environment. Thorough knowledge of these tools enables a gas plumber to perform installations and repairs with precision and safety, ensuring that all systems function correctly.

Essential Equipment for Gas Specialists

Gas plumbers rely on specific tools and equipment designed to handle the unique challenges of working with gas lines. One essential item is a manometer, which measures gas pressure and helps ensure systems operate within safe limits. Availing specialized leak detection equipment allows gas plumbers to identify potential hazards quickly, ensuring both safety and compliance with regulations.

Additionally, gas plumbers often utilize gas-fitting equipment, such as wrenches and pipe cutters, specifically designed for working with gas pipes. These tools must be durable and reliable, as they are crucial for maintaining the integrity of gas systems. Safety gear, including goggles and gloves, is also a vital part of a gas plumber's toolkit to protect against potential hazards while working.

FAQS

What is the main difference between a plumber and a gas plumber?

The main difference lies in their areas of expertise. Plumbers handle water supply, drainage, and sewage systems, while gas plumbers specialize in the installation and maintenance of gas lines and appliances.

Do gas plumbers need special certifications?

Yes, gas plumbers require specific certifications and licenses that demonstrate their competence in working with gas systems, which often includes extensive training and exams.

Can a regular plumber perform gas plumbing tasks?

No, a regular plumber is not qualified to perform gas plumbing tasks unless they have obtained the necessary gas plumbing certifications and licenses.

What tools are essential for gas plumbers?

Essential tools for gas plumbers include gas leak detectors, pressure gauges, pipe wrenches, and specific fittings designed for gas lines.

How long does it take to become a certified gas plumber?

The time required to become a certified gas plumber can vary, but it generally involves several years of training, apprenticeships, and passing certification exams, often taking about 2-5 years in total.