Table Of Contents

Safety Standards for Gas Workers

Safety standards for gas workers are critical to ensuring the well-being of both the professionals and the communities they serve. A gas plumber must be well-versed in the regulations set forth by local and national authorities. Proper training and certification programs are essential for equipping these workers with the skills needed to navigate potentially hazardous situations. Personal protective equipment (PPE) is also a key component, providing a necessary barrier against risks associated with gas work.

In addition to established safety measures, regular assessments and audits are mandatory. Gas plumbers must adhere to protocols that promote safe practices while conducting installations or repairs. Understanding the potential dangers of gas leaks and proper ventilation is fundamental to their role. Ensuring compliance with safety standards not only protects gas plumbers but also safeguards the public from unforeseen incidents.

Protective Measures and Regulations

Gas plumbers must adhere to stringent safety standards to minimize risks associated with gas installations and maintenance. Regulatory bodies establish guidelines that dictate the required training and certifications for professionals in the field. These regulations ensure that gas plumbers are knowledgeable about safe practices, proper equipment use, and emergency response protocols. Compliance with these standards not only protects the workers but also safeguards homeowners and businesses from potential hazards.

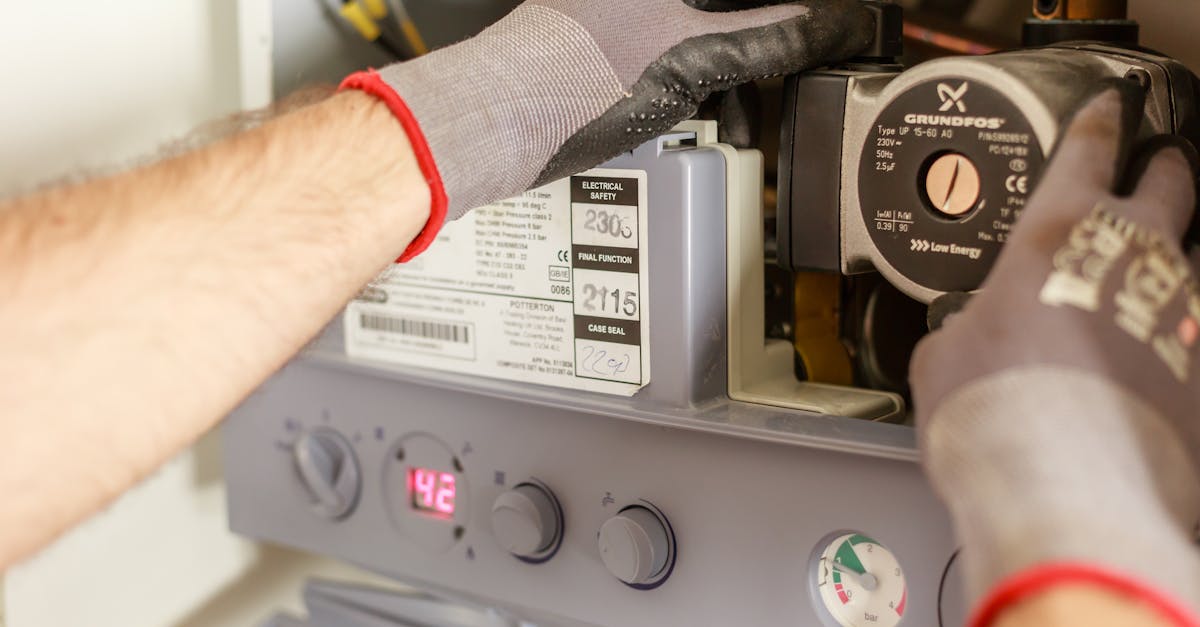

In addition to training, personal protective equipment (PPE) is crucial for gas plumbers. This equipment may include gloves, safety goggles, and appropriate clothing to protect against leaks and other hazards. Regular inspections and audits are also necessary to ensure that gas systems are functioning safely and efficiently. Local and state regulations often mandate these practices, reinforcing the importance of ongoing vigilance in the gas service industry.

The Importance of Gas Maintenance

Regular maintenance of gas systems is essential for ensuring the safety and efficiency of gas appliances. A gas plumber plays a crucial role in this process by performing routine inspections and servicing of gas lines, boilers, heaters, and other appliances. Preventative maintenance helps to identify potential issues before they escalate into serious problems. This proactive approach can extend the lifespan of gas equipment and enhance overall system performance.

In addition to safety benefits, proper gas maintenance is vital for energy efficiency. Systems that are well-maintained operate more effectively, reducing unnecessary energy consumption. A skilled gas plumber can optimize the performance of gas appliances through adjustments and repairs, ensuring they work at peak efficiency. Regular maintenance not only promotes safety but also contributes to lower utility bills and a reduced environmental impact.

Routine Checks and Emergency Services

Routine checks are essential for ensuring the safe operation of gas systems. A gas plumber performs these inspections to identify potential issues before they escalate into more significant problems. Regular maintenance can help prevent gas leaks, reduce the risk of carbon monoxide buildup, and ensure compliance with safety regulations. These checks often involve testing pressure levels, inspecting connections, and verifying that appliances function properly.

In case of a gas emergency, immediate action is crucial. A gas plumber is trained to respond quickly to hazardous situations such as leaks or appliance malfunctions. They have the expertise to secure the area, assess the damage, and make necessary repairs or replacements. By providing rapid response services and accurate diagnostics, gas plumbers play a vital role in minimizing risks and restoring safety for both residential and commercial properties.

The Future of Gas Work

The landscape of gas work is evolving rapidly due to advancements in technology and shifting energy demands. Innovative tools and techniques are being developed to streamline the installation and maintenance of gas systems. Additionally, the increasing focus on sustainability is pushing gas plumbers to adapt by becoming proficient in hybrid systems that incorporate renewable energy sources alongside traditional gas options.

As regulations and safety standards become more stringent, the role of a gas plumber will likely become more specialized. Professionals in this field will need ongoing education to stay current with the latest practices and technologies. Employers are placing greater emphasis on training, ensuring their teams can effectively manage both traditional gas systems and newer, environmentally friendly alternatives. Skills in diagnostics and problem-solving will be crucial as the industry continues to embrace modernization.

Trends Influencing the Gas Industry

The gas industry is undergoing significant changes due to advancements in technology and shifts in energy consumption patterns. Increasingly, consumers are opting for more energy-efficient solutions. This trend has led to a greater demand for skilled professionals, including gas plumbers, who can install, maintain, and repair modern gas appliances and systems. As renewable energy sources become more prominent, gas plumbers are also adapting their skills to accommodate hybrid systems that integrate both gas and electric technologies.

Regulatory changes play a crucial role in shaping the gas industry. Stricter safety standards require ongoing training and certifications for gas plumbers. Adhering to updated regulations ensures that these professionals are equipped to handle new technologies and maintain high safety protocols. This shift not only enhances job security for professionals in the field but also fosters a culture of continuous learning and adaptation to emerging trends in energy use and safety.

FAQS

What is the term for someone who specializes in gas installation and maintenance?

The term for someone who specializes in gas installation and maintenance is typically a "gas technician" or "gas fitter."

What qualifications do gas workers need?

Gas workers usually need to complete specific training programs and obtain relevant certifications or licenses, which may vary by state or country.

Are there different types of gas workers?

Yes, there are different types of gas workers, including gas fitters, gas engineers, and gas service technicians, each with specialized skills and responsibilities.

What safety measures should gas workers follow?

Gas workers should follow strict safety standards, including wearing protective gear, conducting thorough risk assessments, and adhering to regulations to prevent accidents and ensure safe working conditions.

How often should gas systems be maintained?

Gas systems should undergo routine checks and maintenance at least once a year, but the frequency may vary based on specific regulations and the type of gas appliances used.